TL;DR

- Autonomous inventory AI saved $55 million in a single deployment

- System predicts demand at store/SKU level and rebalances inventory without human approval

- Decision speed went from days (analyst review) to minutes (automated action)

- Best for: distributed retail, manufacturing, any network with millions of inventory movements

- Key shift: machines make routine decisions, humans focus on exceptions and strategy

AI-powered autonomous inventory management can save tens of millions by predicting stockouts and rebalancing supply across thousands of locations—in minutes, not days.

Walmart has a problem most businesses would envy: scale.

Five thousand stores. Millions of products. Billions of inventory movements per year. At that scale, small inefficiencies compound into massive waste.

A few extra units sitting too long in one distribution center while another location sells out. Multiply by millions of SKUs. Multiply by thousands of locations. The cost becomes staggering.

“Traditional inventory management is reactive. Something goes wrong, someone notices, someone fixes it. By then, you’ve already lost the sale or absorbed the waste.”

Walmart decided to flip the model. What if the system fixed problems before anyone needed to notice?

The Old World

For decades, inventory management followed a pattern.

Systems generated reports. Analysts reviewed reports. Analysts identified problems. Analysts created orders. Orders moved product. Days passed between problem and solution.

“By the time a human noticed an overstock in one location and a potential stockout in another, the moment had often passed. The sale was lost. The excess was aging.”

Worse, humans could only watch so much. Even a team of analysts couldn’t monitor millions of data points simultaneously.

“We had blind spots. Always. Some imbalances never got caught until they became losses.”

The Vision

Walmart’s supply chain team imagined something different: a system that continuously monitored inventory across every location, predicted imbalances before they happened, and initiated corrective action automatically.

Not “alert a human” — actually fix the problem.

“We wanted AI that didn’t just tell us what was wrong. We wanted AI that made decisions and executed them while humans were sleeping.”

The goal was ambitious: autonomous inventory rebalancing across 35+ manufacturing facilities and thousands of retail locations.

The Data Foundation

Before AI could act, it needed to see.

The system ingests data from everywhere:

- Real-time sales from every register

- Weather forecasts affecting demand

- Local events (concerts, sports games, holidays)

- Historical patterns by location and product

- Current inventory levels across all nodes

- Transit times between distribution points

- Supplier lead times and reliability scores

“We built a neural network that knows what’s selling, what’s sitting, what’s in transit, and what might spike tomorrow.”

The data flows continuously. Not hourly reports. Not daily batches. Live.

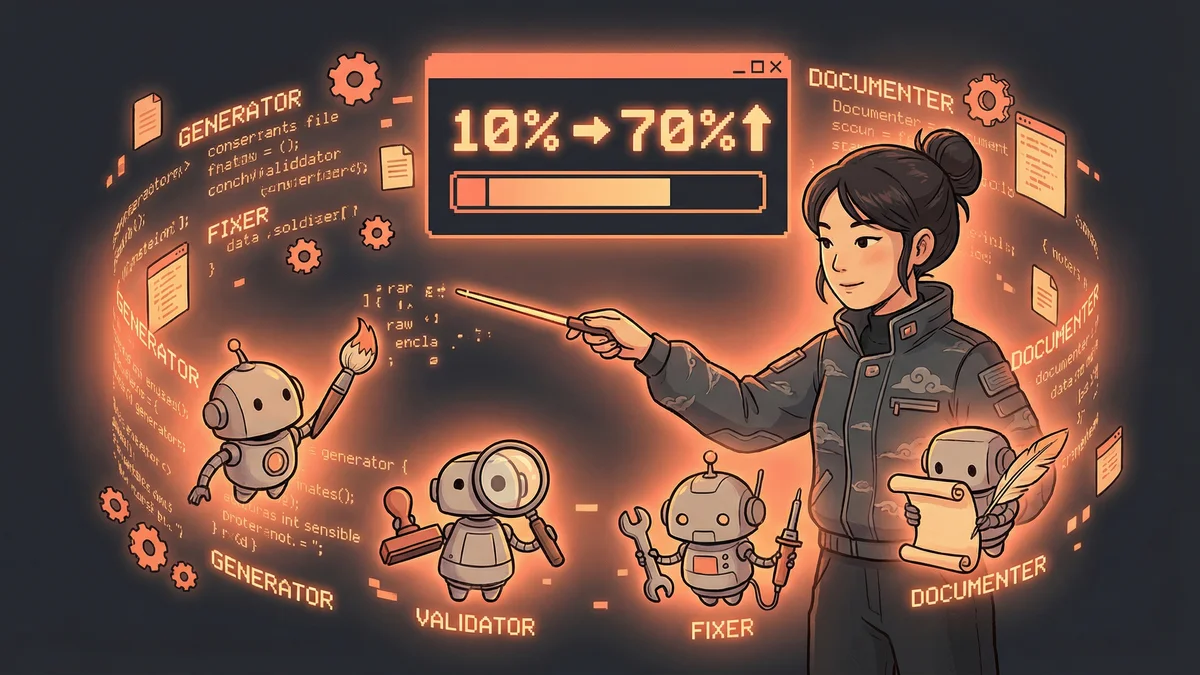

The Prediction Engine

With comprehensive data, the system predicts demand at granular levels.

Not just “we’ll need more sunscreen in summer.” But “Store #4721 in Phoenix will sell 47 more units of SPF 50 than normal next Tuesday because of the outdoor festival downtown.”

“The predictions are specific. Location-specific. Date-specific. Event-aware. Weather-aware.”

The system models demand curves for every product at every location, adjusting in real-time as conditions change.

The Autonomous Action

Here’s where it gets radical: the system doesn’t just predict. It acts.

When the algorithm detects an imbalance — overstock in one distribution center, predicted shortage in another — it doesn’t create an alert for humans to review. It issues the redirect order directly to logistics providers.

“The system says: move 500 units from Distribution Center A to Distribution Center B. That order goes out. Trucks get assigned. Product moves. No human touched it.”

This happens continuously, around the clock, across the entire network.

The Results

The numbers validated the approach.

$55 million saved in a single deployment by reducing waste and preventing stockouts.

Projected $50 million more in manufacturing waste reduction as the system expanded.

Stockout rates dropped. Products were where customers wanted them before customers knew they wanted them.

“We’re not managing inventory anymore. We’re orchestrating it. The system sees patterns humans can’t see and acts faster than humans can act.”

The Decision Speed

The speed difference is transformative.

Old model: Problem emerges → Report generated → Analyst reviews → Decision made → Order created → Action taken. Days.

New model: Pattern detected → Prediction generated → Decision made → Action taken. Minutes.

“We went from decision-in-days to decision-in-minutes. That gap is the difference between catching an opportunity and missing it.”

For perishables, the speed matters even more. A few hours of unnecessary sitting means expired product.

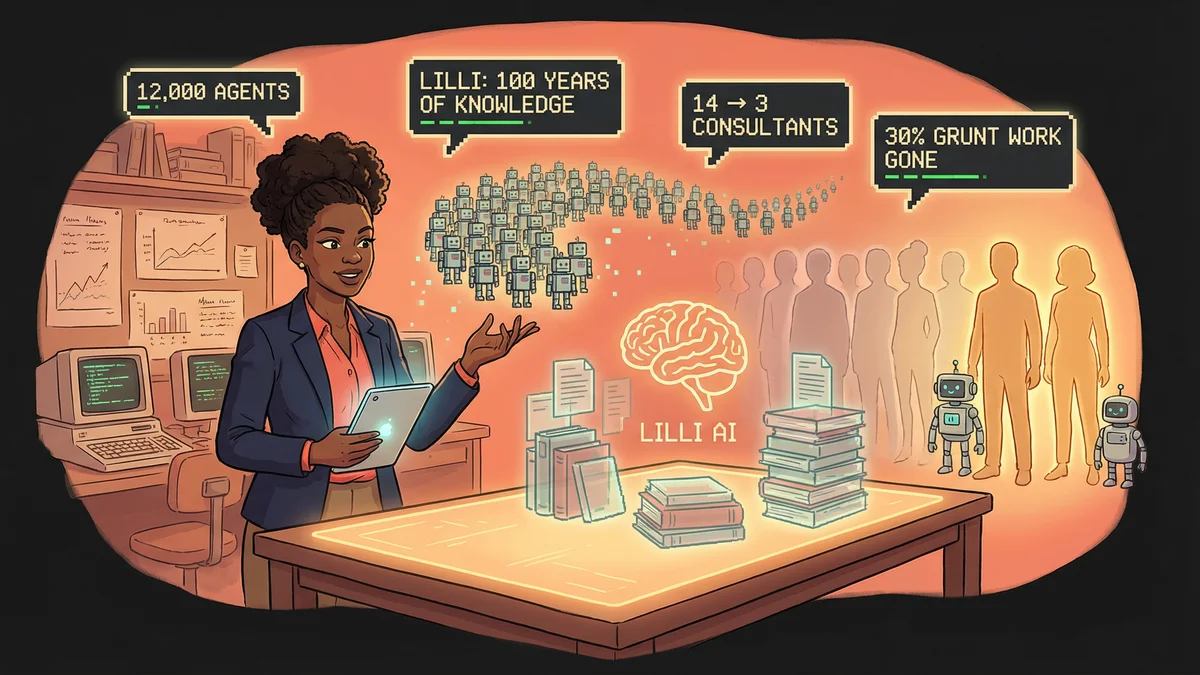

The Human Role Evolution

The system didn’t eliminate jobs. It changed them.

People who used to spend days generating reports now spend time on exceptions — the unusual situations the AI flags but can’t resolve autonomously.

Strategic planning became more important. Instead of fighting fires, teams could think about long-term supply chain architecture.

“We moved from people making decisions supported by machines to machines making most decisions guided by people.”

Humans set the parameters, monitor the outcomes, and intervene on genuine anomalies. The AI handles the routine.

The Learning Loop

The system improves continuously.

Every prediction gets compared against actual outcomes. Did the Phoenix store actually need those extra sunscreen units? If the prediction was wrong, why?

“The AI learns from its mistakes. It gets better at predicting local demand patterns, event impacts, weather sensitivity. Each day it’s smarter than the day before.”

Error patterns get analyzed. If the system consistently underestimates demand for certain products, the model adjusts.

The Global Expansion

What worked in the US expanded internationally.

The same architecture now manages inventory in Mexico and other markets. Different demand patterns, different logistics constraints, same autonomous approach.

“The playbook is portable. Train the model on local data, connect it to local logistics, let it learn the regional patterns.”

Cultural differences in shopping behavior, different holiday calendars, different weather patterns — the AI adapts to each market.

The Philosophical Shift

Walmart’s leadership describes the change as fundamental.

Old thinking: humans decide, machines execute. New thinking: machines decide routine matters, humans decide exceptional matters.

“We crossed a line that many companies haven’t. We gave the AI genuine authority to move product, spend money, direct logistics. That requires trust.”

Trust was earned gradually. Small pilots proved the concept. Success expanded the scope.

The Guardrails

Autonomy doesn’t mean unlimited freedom.

The system operates within parameters:

- Maximum dollar value per automated decision

- Prohibited actions without human approval

- Escalation triggers for unusual patterns

- Kill switches for emergencies

“The AI can redirect inventory freely within bounds. Beyond those bounds, it asks for permission.”

Humans still own the strategy. The AI implements the strategy faster than humans could.

The Competitive Moat

Self-healing inventory creates advantages competitors can’t easily replicate.

“Our products are where customers want them. Our waste is lower than competitors. Our capital efficiency is higher. That’s not luck — it’s intelligence.”

The system represents years of data accumulation, model training, and operational learning. Starting from scratch would take competitors years.

“By the time they catch up, we’ll be further ahead. Intelligence compounds.”

The Pattern for Others

Walmart’s approach offers lessons for any organization managing distributed inventory.

Invest in data infrastructure. The AI can only be as smart as the data it sees.

Start with predictions before actions. Build trust in the forecasts before letting the system act on them.

Design for exceptions. The goal isn’t 100% automation — it’s handling the 95% that’s routine so humans can focus on the 5% that matters.

Measure obsessively. Know whether the autonomous decisions are good decisions.

“Most companies stop at prediction. The real value is prediction plus action. That’s where the savings actually happen.”