TL;DR

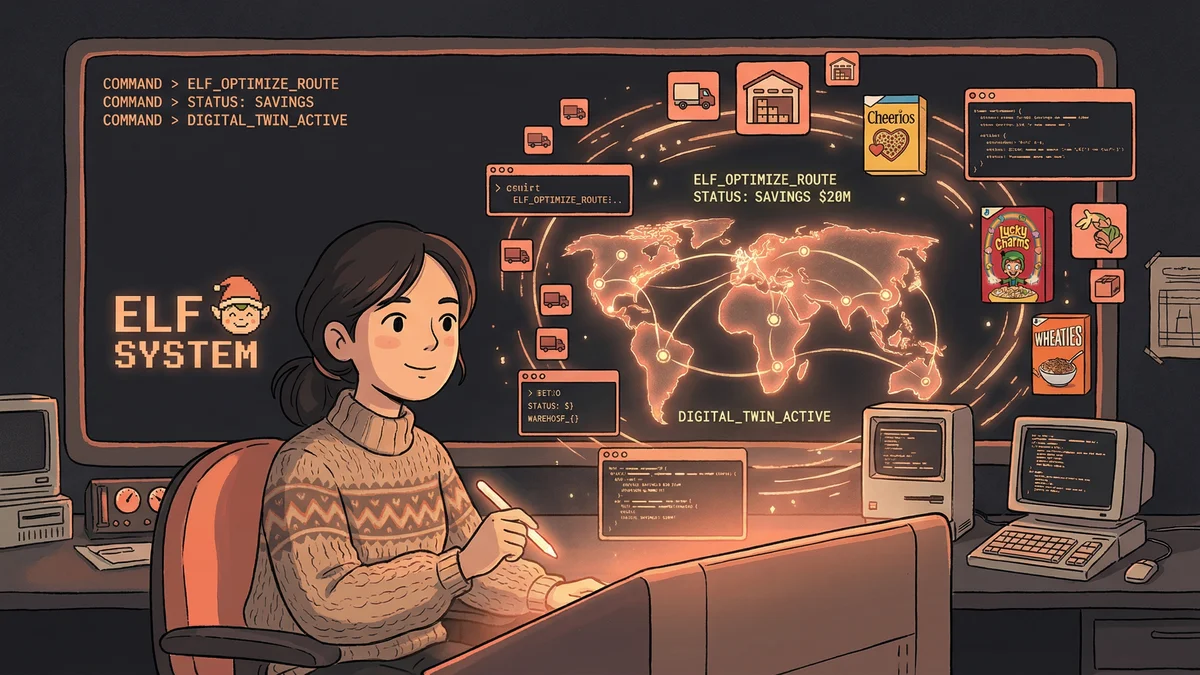

- General Mills saved $20M+ in logistics costs with their ELF digital twin system

- Decision time dropped from one day to one minute for shipment routing

- Built on Palantir platform to simulate 35 facilities and 5,000+ daily shipments

- Best for: Enterprise supply chain and logistics optimization at scale

- Key lesson: Real AI value comes from boring operational improvements, not flashy demos

General Mills proved that a cereal company can achieve $20 million in AI savings by building a digital twin that makes 5,000 daily routing decisions in minutes instead of days.

General Mills moves cereal. A lot of cereal.

Cheerios, Lucky Charms, Wheaties—products that seem simple until you realize the logistics behind them. Thirty-five manufacturing facilities. Thousands of distribution routes. Products with shelf lives that demand precision timing.

“A box of Cheerios sitting in the wrong warehouse for an extra week means lost freshness, lost margin, lost customer trust.”

The company processes 5,000+ shipments every day. Each one a decision: which truck, which route, which warehouse, which timing. Multiply by 5,000. Multiply by 365.

The old way? Experienced logistics managers making decisions supported by spreadsheets and intuition.

The new way? Something General Mills called ELF.

The digital twin

ELF—End-to-End Logistics Flow—isn’t traditional software. It’s a digital twin built on Palantir’s platform.

A digital twin creates a virtual mirror of physical operations. Every truck, every warehouse, every product—simulated in real-time. Changes in the simulation reveal what would happen in reality.

“We can test a routing change against the digital twin before touching a single truck. What used to be a risky experiment became a safe simulation.”

The twin doesn’t just reflect reality. It predicts it.

Weather patterns that affect trucking routes. Seasonal demand spikes. Manufacturing delays that cascade through the supply chain. ELF sees the connections human planners miss.

One minute instead of one day

The transformation was immediate.

Decisions that used to take a full day—analyzing routes, checking capacity, coordinating across facilities—now take one minute.

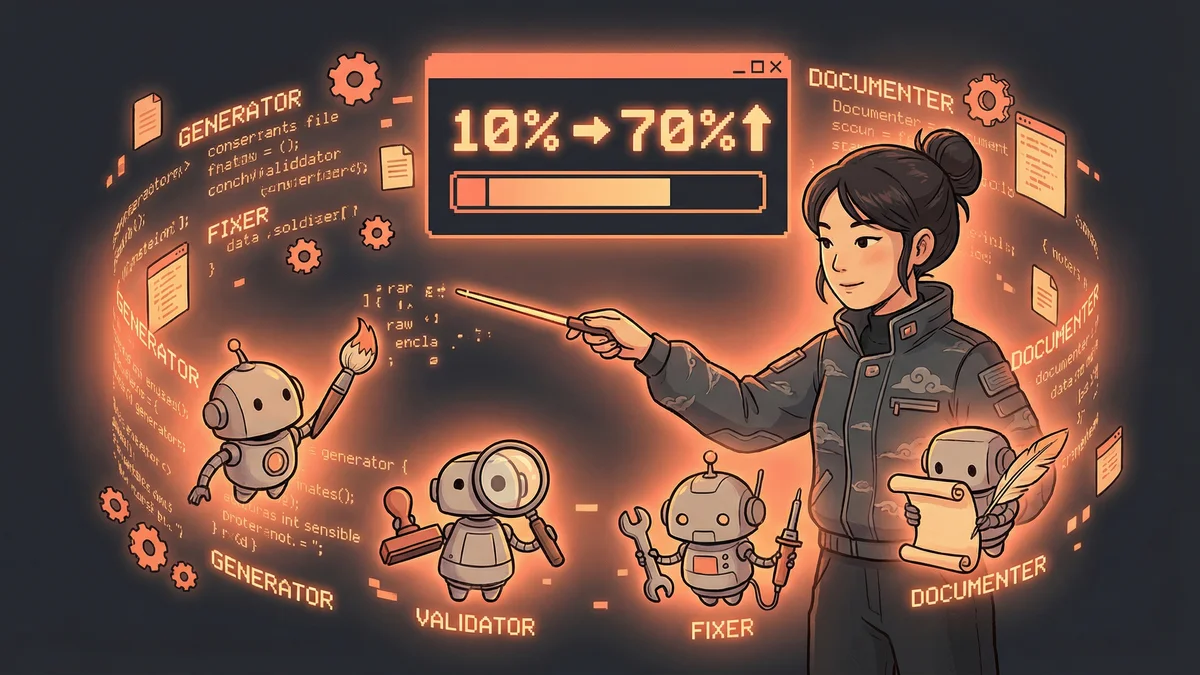

Not because humans got faster. Because most decisions don’t require humans anymore.

“ELF handles the routine calls. When a shipment needs routing from factory to distribution center, the system already knows the optimal path. Human planners focus on exceptions and strategy.”

The 5,000 daily shipments still move. But now they move with AI optimization instead of spreadsheet approximations.

The results

Since fiscal year 2024, General Mills documented $20+ million in logistics savings.

That’s not the projection. That’s what’s already in the bank.

The company projects $50+ million in manufacturing waste reduction as the digital twin expands into production optimization.

“We’re not saving money by cutting corners. We’re saving money by eliminating waste—trucks running half-empty, inventory sitting too long, routes that don’t make sense.”

From people with machines to machines with people

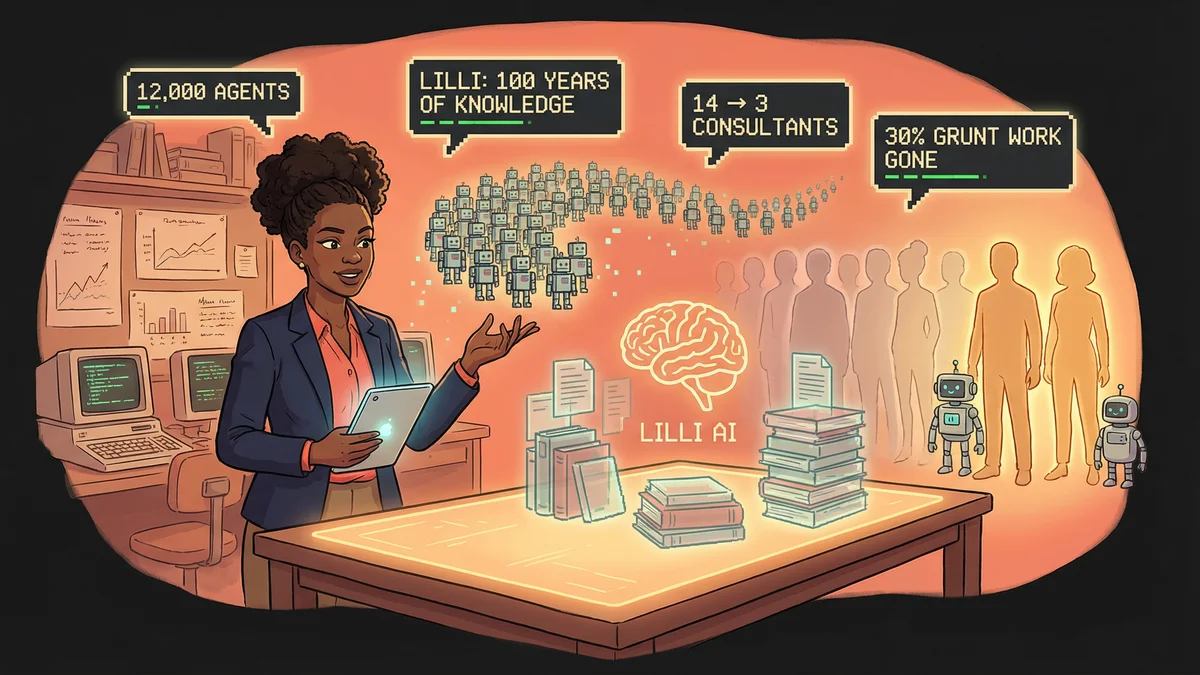

General Mills described the shift with unusual clarity:

“We moved from people making decisions supported by machines to machines making most decisions guided by people.”

The reversal matters.

Old model: Humans decide, software helps. New model: Software decides, humans oversee.

“Our logistics managers used to spend 80% of their time on routine routing decisions. Now they spend 80% of their time on strategic improvements. Same people, transformed role.”

What the food industry teaches

General Mills isn’t a tech company. They make food.

That makes their AI success more instructive than Silicon Valley case studies. If a cereal manufacturer can deploy digital twins at scale, the technology is ready for any enterprise.

The lessons:

Start with the mess. Logistics seems simple until you examine it closely. General Mills didn’t digitize clean processes—they tackled the ugliest, most complex workflows first.

Accept the inversion. Letting machines make decisions feels wrong until you see the results. The shift from “humans decide” to “machines decide with human oversight” requires cultural change, not just technical deployment.

Measure the unsexy stuff. $20 million in logistics savings doesn’t make headlines like AI chatbots. But it hits the bottom line harder.

“AI glamour goes to the flashy demos. AI value lives in the boring operational improvements.”

The compounding effect

The $20 million is just the starting point.

Every optimization ELF makes generates data. That data trains better predictions. Better predictions enable more optimizations.

“We’re not just saving money. We’re building a system that gets smarter every day. Next year’s savings will exceed this year’s.”

The digital twin learns. The company benefits.

And somewhere, Cheerios arrive fresher, faster, at lower cost.